The impacts of digital technologies on the industry of the future

Industry is set for a real revolution. The arrival of digital technologies has led to reviewing the whole production system, and even the way products are designed. A journey into the future with Pascal Brier, Executive Vice-President of Altran, in charge of Innovation.

Digital technologies and connectivity, cobotics, additive manufacturing and virtual reality: the juxtaposition of these technological innovations creates a cyber-physical environment that results in completely rethinking the way assets and industrial processes work. The industry of the future will be an industry in the era of the digital revolution, capable of producing more smartly, more efficiently, more quickly, more safely, and more cleanly. Pascal Brier identifies four major impacts of the digital revolution on the industrial world.

1. Improved performance and flexibility

Being interconnected, the means of production will be able to not only self-regulate by reacting immediately to any problems but also to self-monitor with preventive maintenance made possible by multiple sensors. This will mean a significant decrease in random events and delays. And in addition, by having full control over their production system, manufacturers will be able to produce on demand. The objective is “zero stock” with a consequently drastic reduction in the costs generated by unsold items. Pascal Brier quotes the example of the pharmaceutical industry: “it’s possible to imagine that in the future certain medicines and medical devices will be manufactured singly, on the basis of the needs of consumers”.

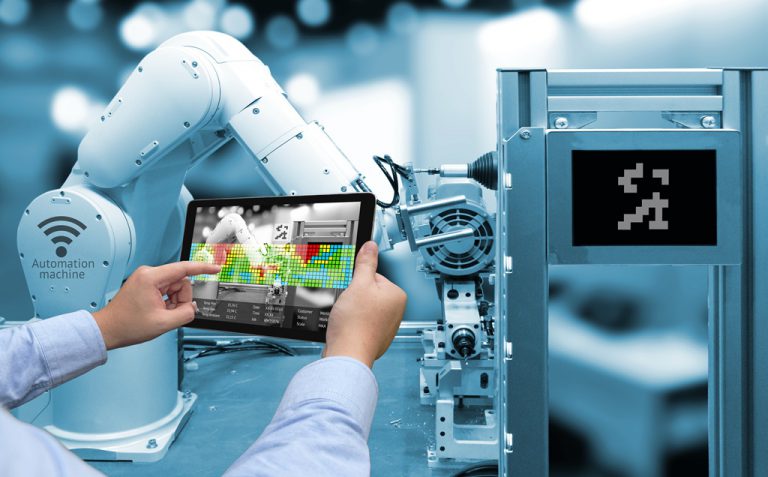

2. Increased productivity

Collaborative robots (cobots) will significantly increase the productivity of operators and improve their safety and well-being. “For example, in the aviation industry, there are often voluminous or very heavy parts to be handled and work may be carried out at great heights. In the future,” explains Pascal Brier, “thanks to the use of exoskeletons with articulated arms, operators will be able to carry out these tasks without damaging their backs, or having to go back and forth on bridges or ladders.”.

3. A massive reorganization of the supply chain

Traditional production models sometimes lead to having to relocate certain factories in order to make them profitable by producing a lot at low cost. Additive manufacturing does not have the same problem: it is profitable even if it only produces a few parts. Its appearance is therefore bringing about a paradigm shift: the emergence of local micro-factories. Thanks to 3D printing, they will be able to maintain and repair all industrial goods locally. Which means that in the future, if you need a part for your car, it can be produced directly in the garage closest to you, rather than being ordered from the factory. Pascal Brier enthuses: “We are in the process of inventing an economy that complements the traditional factories that are based on a Taylorism model.”.

4. Mass customization

Henri Ford said, “You can choose any colour for the Model T Ford, as long as it’s black.” The industry of the future is based on the opposite principle: we are entering the era of mass customization, where production responds to demand, where virtual reality makes it possible to push the limits of the imagination ever further. This opens great possibilities for agile businesses able to make it a real business lever. Obviously, digital transformation is not a straightforward exercise. We need to be able to identify the right technologies, ensure the commitment of both operators and supervisors, and rely on the support of experts. And, like all revolutions, this one has begun silently: we are in a transition phase, which is likely to last another decade.

Nonetheless, Pascal Brier asserts that industry must prepare itself and understand the impacts and challenges this new revolution will bring. The movement is in gear and the transformation is on its way. The industry of the future will soon meet up with the present.