What will the industry of the future look like?

Industry is set for a real revolution. The arrival of digital technologies has led to reviewing the whole production system, and even the way products are designed. A journey into the future with Pascal Brier, Executive Vice-President of Altran, in charge of Innovation.

The Germans call it industry 4.0, the Americans smart manufacturing, and in France it is known as the “industry of the future”. Whatever term is used, the idea is the same: industry is at the dawn of a major revolution. The fourth in its history, to be exact.

Since the 18th century, four innovations have successively overturned industrial conventions: the steam engine in the 18th century, electricity at the end of the 19th century, computing in the 1950s and, in the last five years or so, cyber-physical systems. That is, all the new digital, software and hardware technologies that revolutionize the way we design and produce goods and services.

How was this fourth industrial revolution born? The current major upheaval corresponds to the simultaneous arrival on the market of a number of innovative technologies.

1. Digital technologies and connectivity

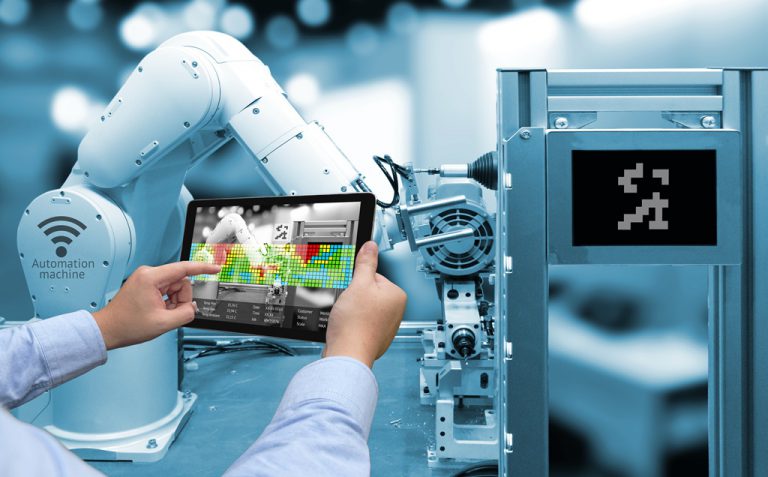

In the industry of the future, all industrial assets will be connected within the same factory as well as between factories. In practice, sensors at each stage will exchange data in real time which will then be analysed to ensure optimal operation (preventive and predictive maintenance, production scheduling, etc.). “The factory of the future will be reorganized on a network model; it will become a real connected digital platform,” says Pascal Brier.

2. Robotics in collaboration with people

A new type of robot is emerging – they are known as “cobots” or “collaborative robots”. Until now, robots used in factories were designed to work alone and perform single tasks. Cobots are intelligent robots designed to complement people in order to achieve more with less effort.

3. Virtual Reality

3D modelling means a new conception of the industrial environment. With virtual reality, it is of course possible to design and simulate a product from the design phase (by creating its digital twin), but it is also feasible to design and simulate an entire production chain completely virtually (position of machines, operators, pace of production, simulation of procedures and incidents, etc.), and then test it. Before taking it into the real world.

4. Additive manufacturing

Currently, the manufacturing model for industrial parts is based on eliminating material. From a block material (steel, aluminium, titanium, etc.), it consists of eliminating all the parts deemed useless in order to end up with the shape of the final part. This traditional manufacturing method is the main reason industry generates so much scrap (up to 70% of the material used). Additive manufacturing – also called 3D printing – is based on the opposite principle: only the material that is strictly necessary is used. Controlled by a computer, the successive layers are deposited until they reach the desired final shape. This new approach will make it possible to design lighter, more complex, potentially lower cost products while paving the way for a very significant reduction in industry’s ecological footprint.

To read next: the impact of digital technologies on the industry of tomorrow